Auto Repair Shop Trench Drains

Auto repair shops face constant exposure to oil, grease, and chemical runoff. Effective trench drain systems are essential to maintain clean, safe, and compliant work environments. A properly engineered drainage solution captures wash water, lubricants, and runoff before they enter the sewer system — protecting both flooring and environmental integrity. TrenchDrainCo systems are built to handle heavy wheel loads, chemical exposure, and daily wash-down activity.

Key Requirements

-

Load Rating

Typically C250 to E600, depending on the type of vehicle traffic.

• Light-duty shops (cars, SUVs): C250.

• Fleet and truck repair bays: D400–E600.

Channels must handle point loads from lifts, jacks, and tire contact.

-

Material Durability

Exposure to oils, fuels, solvents, and detergents requires chemically resistant materials.

• Fiber-Reinforced Concrete (FRC) or Polymer Concrete channels resist deformation and degradation.

• HDPE channels with chemical-resistant coating for moderate exposure.

• Ductile-iron or galvanized steel grates rated for vehicle traffic.

• Stainless steel grates for wash bays or areas with corrosive cleaners.

-

Site Conditions

• Flat indoor slabs with controlled slope (typically 1–2%) toward drains.

• Floor drains should connect to oil/water separators per code requirements.

• Channels must be flush-mounted to accommodate vehicle lifts, creepers, and rolling equipment.

• High resistance to thermal and mechanical shock from weld sparks or hot fluids.

-

User Requirements

• Slip-resistant grates to prevent worker injury.

• Chemical resistance to oil, brake fluid, and solvents.

• High-capacity drainage for wash-down and rainwater entering open bays.

• Ease of maintenance: Removable grates and debris baskets for quick cleaning.

• Safety compliance: Integration with environmental and EPA discharge standards.

Recommended TrenchDrainCo Systems

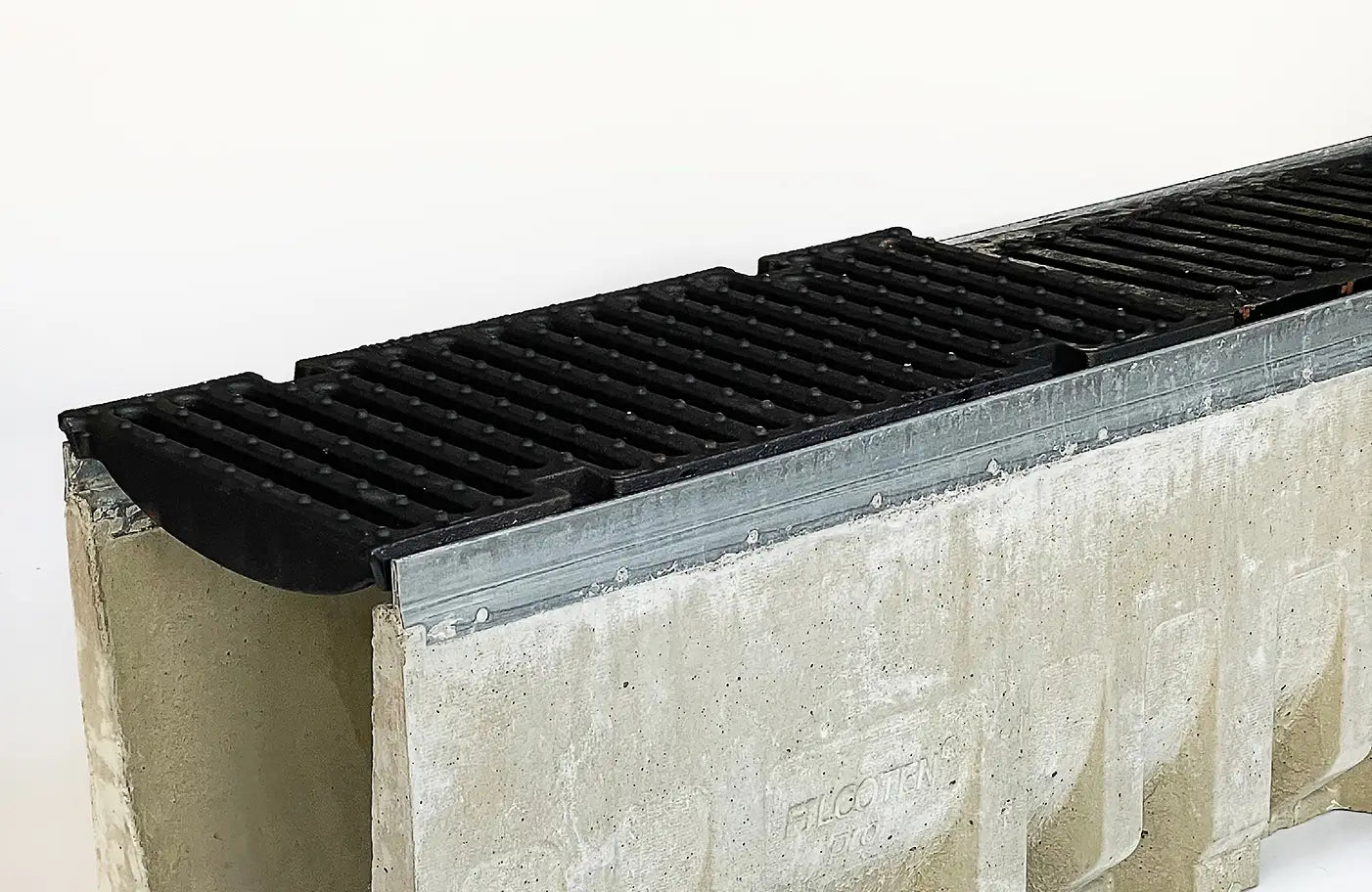

TrenchDrainCo 300 Series

Heavy-duty fiber-reinforced concrete channels for vehicle bays and shop floors.

TrenchDrainCo LEO 1200

Cast-iron grates with C250–E600 load ratings for workshop environments.

TrenchDrainCo Quicksilver

Fully stainless system for chemical-resistant, high-temperature wash-down zones.

Engineering Notes

When designing trench drains for automotive environments:

- Always include sediment traps or catch basins to intercept debris and oil.

- Maintain alignment with shop floor slopes to prevent standing fluids.

- Ensure the drain layout supports equipment spacing and lift post positions.

- Use corrosion-resistant fasteners and anchors to handle moisture and degreasers.

- Validate system capacity for simultaneous use of multiple wash bays.

Protect your shop floor and stay compliant

Request a custom drainage layout engineered for your auto repair or fleet maintenance facility.

📞 Call us: 212-946-3798

📧 Email us: info@trenchdrainco.com