Chemical Processing Facility Trench Drains

Chemical processing facilities demand drainage systems capable of handling corrosive fluids, high temperatures, and heavy industrial loads. Whether managing washdown water, chemical spills, or process drainage, these environments require non-reactive, high-strength trench drain systems that protect both workers and infrastructure. TrenchDrainCo systems are engineered for extreme durability, chemical compatibility, and environmental compliance — ensuring long-term reliability in the harshest industrial settings.

Key Requirements

-

Load Rating

Typically D400 to F900, depending on equipment and vehicle traffic.

• Indoor process areas: D400 (forklift and cart traffic).

• Outdoor containment and tanker zones: E600–F900 (heavy truck and drum handling).

-

Material Durability

Drainage components must resist acids, alkalis, solvents, and high-temperature discharge.

• Fiber-Reinforced Concrete (FRC) and Polymer Concrete channels withstand mechanical and thermal stress.

• HDPE or PVC chemical-resistant systems for lightweight installations or retrofit use.

• Stainless steel 316L channels and grates for maximum corrosion resistance.

• Epoxy-lined or coated systems for additional chemical protection in extreme pH environments.

-

Site Conditions

• Continuous exposure to wash down water, process runoff, and chemical containment areas.

• Trench drains must integrate with secondary containment systems and sump pumps.

• Non-slip, spark-resistant grates required for safety in flammable zones.

• System joints sealed with chemical-resistant elastomers (EPDM, Viton) to prevent leakage.

-

User Requirements

• Chemical compatibility: Non-reactive materials for specific acids, bases, or solvents.

• Load capacity: Support for forklifts, tankers, and drum carts.

• Safety: Slip-resistant, spark-proof grates in compliance with OSHA standards.

• Maintenance: Removable grates and accessible channels for decontamination and inspection.

• Environmental compliance: Integration with containment and neutralization systems per EPA and local regulations.

Recommended TrenchDrainCo Systems

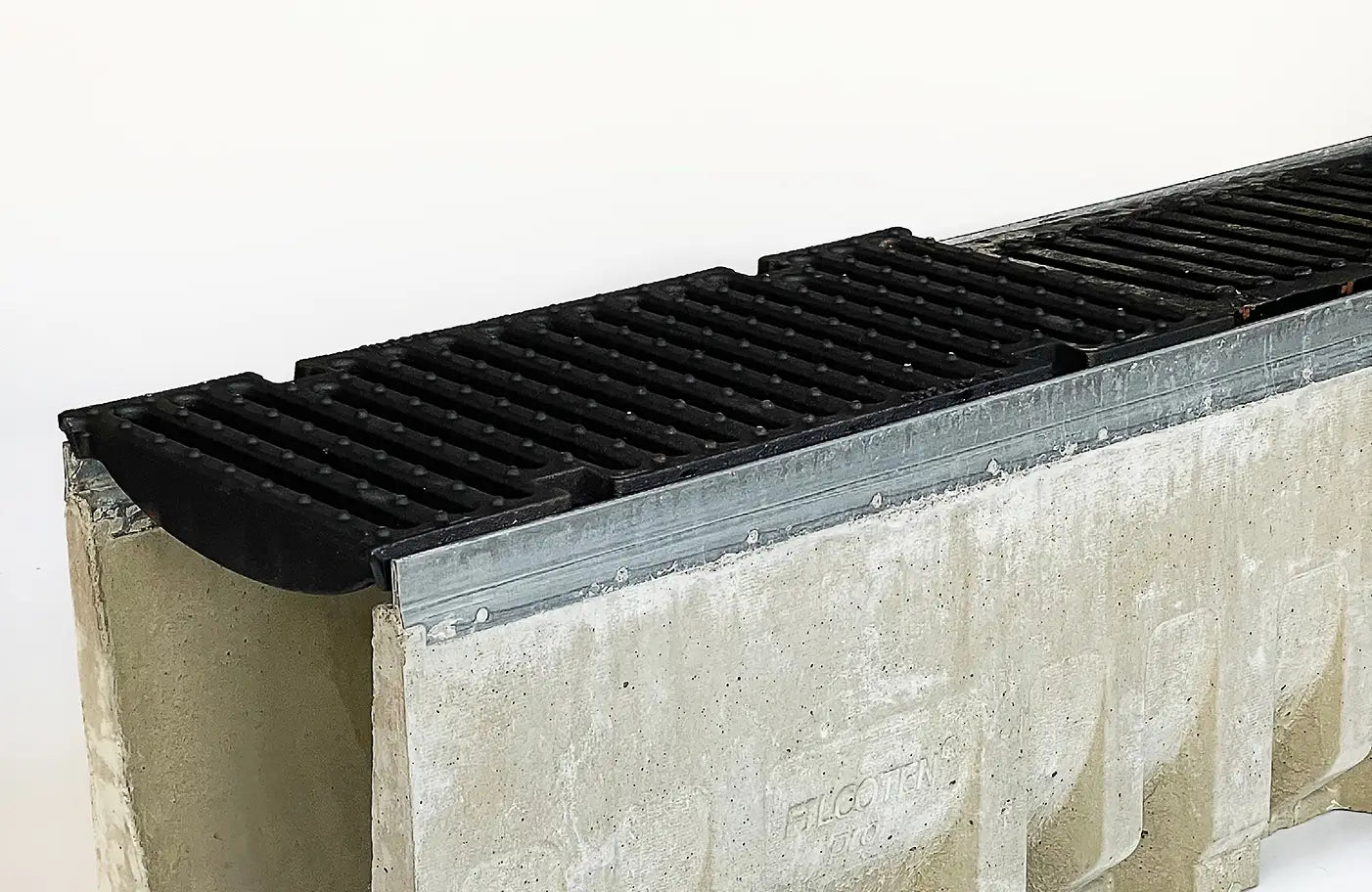

TrenchDrainCo FRC Industrial Series

High-strength fiber-reinforced concrete channels rated up to F900 for heavy industrial applications.

TrenchDrainCo Stainless 316L System

Fully stainless steel channels and grates designed for extreme chemical and thermal resistance.

TrenchDrainCo HDPE Chem-Resist Series

Lightweight HDPE channels for secondary containment or retrofit installations.

TrenchDrainCo Epoxy-Lined System

Polymer concrete channels with epoxy liner for maximum chemical protection and long-term durability.

Engineering Notes

When designing trench drains for chemical processing environments:

- Match channel and grate materials to the plant’s chemical exposure matrix (acids, solvents, caustics).

- Ensure all outlet connections are sealed and directed to containment or treatment systems.

- Use non-ferrous, spark-resistant hardware where flammable chemicals are present.

- Verify temperature ratings for drains exposed to process effluents or steam cleaning.

- Employ fall gradients and access points for efficient flushing and maintenance.

Engineered for the toughest environment

Speak with a TrenchDrainCo engineer to design a chemical-resistant trench drain system tailored to your process and compliance requirements.

📞 Call us: 212-946-3798

📧 Email us: info@trenchdrainco.com