Fire Station Trench Drains

Fire stations operate under demanding conditions — from the constant movement of heavy apparatus to daily wash downs of engine bays. Effective trench drainage is essential for maintaining safety, cleanliness, and structural integrity. TrenchDrainCo trench drain systems are engineered to handle extreme wheel loads, chemical exposure from cleaning agents, and rapid water discharge, all while ensuring long-term reliability and compliance with firehouse facility standards.

Key Requirements

-

Load Rating

Typically D400 to F900, depending on apparatus and vehicle type.

• Apparatus bays and drive-throughs: D400–E600 (fire trucks, ladder trucks).

• Exterior aprons and access lanes: E600–F900 for fully loaded rescue and ladder vehicles.

• Interior washdown and maintenance areas: D400 for pedestrian and rolling tool load zones.

-

Material Durability

Fire stations demand systems that can endure heat, water, salt, and mechanical stress.

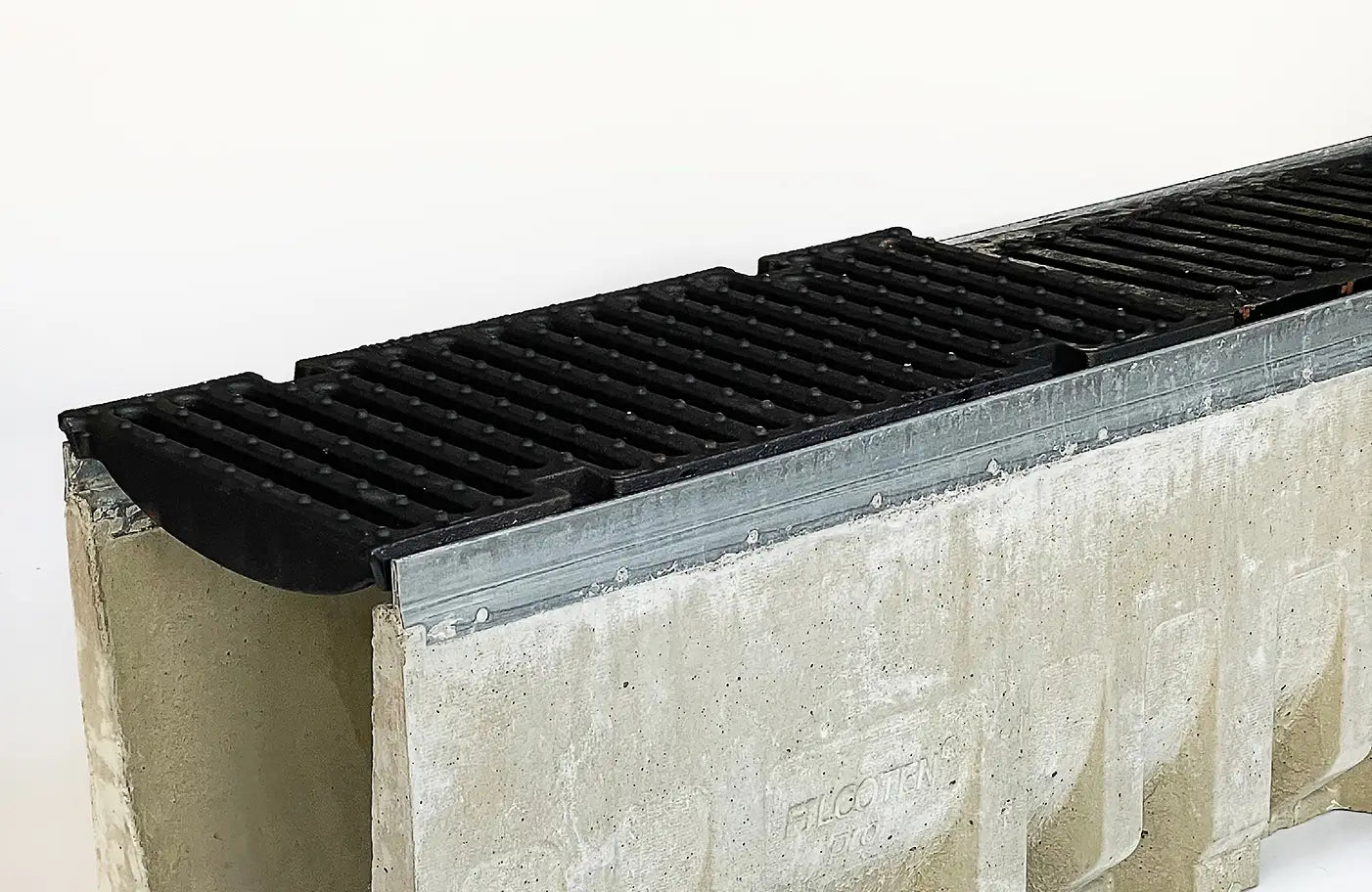

• Fiber-Reinforced Concrete (FRC) or Polymer Concrete channels for high compressive strength.

• Galvanized or ductile-iron grates for maximum load capacity.

• Stainless steel grates in washdown zones where chemical cleaners are used.

• HDPE channels as a corrosion-resistant option in retrofit or lighter-duty sections.

-

Site Conditions

• Frequent washdowns require high-flow capacity and debris interception.

• Drains should align with apparatus bay slopes to prevent pooling or slip hazards.

• Exterior zones exposed to de-icing salts and freeze-thaw cycles demand corrosion-resistant materials.

• Systems must integrate with oil/water separators to ensure environmental compliance.

-

User Requirements

• Safety: Slip-resistant, ADA-compliant, and heel-proof grates for personnel movement.

• Durability: Long-term structural stability under constant vehicular stress.

• Ease of maintenance: Quick grate removal for debris cleaning and inspection.

• Environmental compliance: Drainage routed through approved separators before discharge.

• Performance: Continuous operation despite washdowns, temperature changes, or heavy loads.

Recommended TrenchDrainCo Systems

TrenchDrainCo 300 Series

Fiber-reinforced concrete trench drain system with ductile-iron grates, load-rated up to E600 — ideal for apparatus bays.

TrenchDrainCo LEO 1200

Heavy-duty ductile-iron channel system for drive lanes and exterior aprons.

TrenchDrainCo Quicksilver

Corrosion-resistant stainless steel system for interior cleaning and maintenance zones.

TrenchDrainCo Model 600

Lightweight and easy-to-install option for auxiliary service areas and floor drains.

Engineering Notes

When designing trench drainage for fire stations:

- Align trench drain placement with apparatus bay doors to capture sheet runoff efficiently.

- Include sediment baskets and oil/water separators to prevent hydrocarbon discharge.

- Choose FRC or polymer concrete for high load-bearing and long-term stability under thermal stress.

- Ensure slopes are optimized (1–2%) for rapid water evacuation during washdowns.

- In freeze-prone regions, specify corrosion-resistant and non-spalling materials.

Engineered for performance when it matters most

Talk to a TrenchDrainCo engineer about trench drain systems designed for apparatus bays, aprons, and wash areas.

📞 Call us: 212-946-3798

📧 Email us: info@trenchdrainco.com